News

News

Who am I?

Who am I?

My Monthly Column

My Monthly Column

Important:

•Not interested in anything illegal, politics, drugs, racial discussion, harassment.

The above disclaimers address frequent incorrect assumptions about me that are important to distinguish.

News

News

Who am I?

Who am I?

My Monthly Column

My Monthly Column

Important:

•Not interested in anything illegal, politics, drugs, racial discussion, harassment.

The above disclaimers address frequent incorrect assumptions about me that are important to distinguish.

Technology (Tutorials, Opinions, & More) Technology (Tutorials, Opinions, & More)

Technology Repair Log Technology Repair Log

Vintage Technology Repair Log  Quasar Compu-Matic Remote (1983)

Problem: The remote would not work. Batteries that were fully functional were placed into the remote and there was zero response to touching the buttons. The remote did not work.Troubleshooting: I disassembled the remote. The remote is snapped together with plastic rather than using screws. I take the remote apart by using spuding tools, which are designed to get inbetween the cracks to pry apart the device at the plastic snapping points. So far I have never broken a device by doing this. One shouldn't be discouraged to open up a snapped together plastic device by using spuding tools.

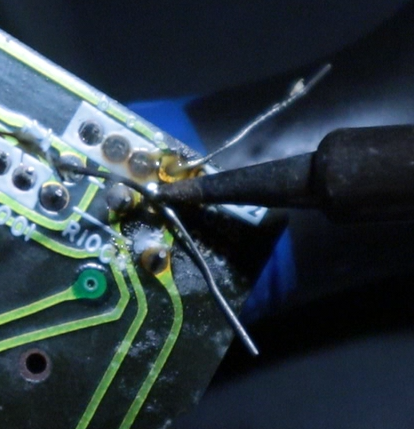

Problem #1: Wires supplying power from the batteries to the board fell off

Solution Step 1: Removing solder where the wires were on the circuit I had to remove the remaining wire from the circit. The first solder joints on the circuit are the ones holding in the wire. Since I need to solder in a new wire, I must remove the old solder so there will be a hole in the circuit for me to feed the new wire into. I applied flux to both solder joints, then heated one solder joint with a soldering iron. After it heated up, I removed the solder with a solder sucker. I had to do this 2 or 3 times to fully remove the solder.

Solution Step 2: Removing the solder and old wire from the battery ports There was still a small amount of wire left where it connects to the battery ports. I also had to remove the solder that originaly connected the wire to the battery port. This had to be done so I could solder in the new wire to the battery port. I heated up the top of the battery port (this is where the solder was) with my soldering iron until it was hot. Then I removed the solder with a solder sucker.

I had to repeat this a few times until most of the solder was gone. However, one again, the wires remained. I worked the wires out of the battery port and through the hole of the battery port, simply by warming the area with my soldering iron and moving the wire out through the hole. Then I got tweezers and pulled the wire away from the battery port.

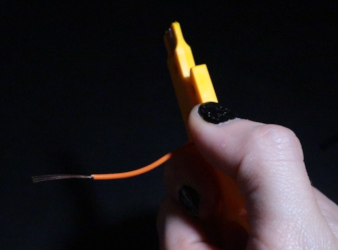

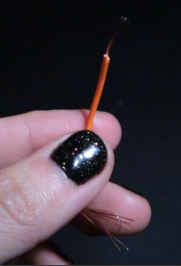

I repeated this for the other wire/battery port. Solution Step 3: Creating new wires I have a box of "Dupont" wires, they have various ends on them such as male male, male female, and female female. However, since I do not need these ends, I cut off the end with wire cutters. I needed exposed wire (not wire covered with casing), so I used a wire stripper to remove the casing and expose plenty of actual wire.

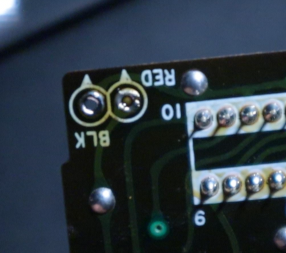

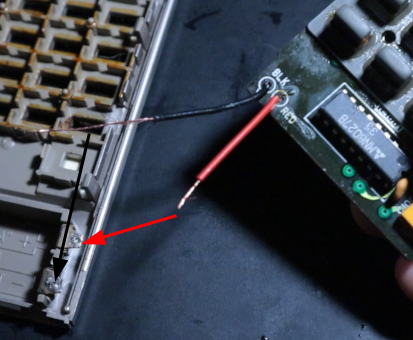

I repeated this for the other side of the wire, and I also made sure this wire was similar in size to the original wires. I twisted the ends of the wire for ease. I chose to make one wire in black and one in red for consistency, but the color of the casing doesn't matter. It's all the same internally. Solution Step 4: Soldering in the new wires to the PCB I fed the black wire through to the hole labeled "black". The end of the exposed wire must come from the bottom of the PCB to the top where all the other solder joints are for consistency's sake.

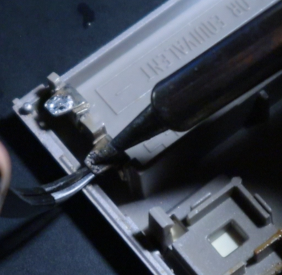

Solution Step 5: Soldering in the new wires to the battery ports  This was more diffcult due to trying to get the wire into the small hole and a strange angle on the battery ports. However, I managed to feed the exposed end of the wire into the hole. On the black wire I was able to feed the wire in from the bottom of the battery port to the top of the port, since the solder will be applied at the top of the port. However, I couldn't get the red wire to feed in via the bottom, eventually having to feed it through the top. (Though later this wire broke and I was able to feed it in via the bottom.)

Notes: These wires I soldered in broke at the same point the original set of wires did. I am fairly certain this is because there was too much abrupt pressure from the wire being bent to fit in the remote's casing. To solve this, I simply repeated this entire process to remove my new set of wires in favor of yet another new set, but with a thicker casing as to be more durable. Now they have no problems.

Problem #2: Suspected bad electrolytic capacitor Solution: I heated up the solder joints for the capacitor, removed the capacitor, and put in a new capacitor of equal value, making sure that the polarity was correct when I replaced the capacitor. This was very quick to do. After finishing this, I trimmed the leads and reassembled the remote with the batteries inside the remote. I pressed the power button by the TV and at first there was no response. I kept trying and after 2-3 tries, the TV came on. I successfully fixed the remote, the original issue was definitely an old capacitor measuing with too high of an ESR. (However, the broken wires were definitely an issue, just not the original issue). Problem #3: Buttons must be pressed pretty hard for the TV to respond. While I did get the remote functioning and working, the buttons had to be pressed fairly hard to get a response. About a week prior to this, I had a VCR remote stop funtioning, so I figured I knew where to start fixing this issue. Solution: I disassembled the remote. I took off the rubber pad buttons and cleaned the circuit where the pad meets the circuit. I assumed the remove had a case of dirty connections, cleaning them would help the remote make a better connection when a button was pressed. After cleaning the board and the rubber pad with rubbing alcohol, I reassembled.

Notes: I'm very glad to have fixed this remote and was pleasently surprised I was able to apply a new set of wires. In times past I would have assumed the remote was fully broken and that there would be no way to fix a remote if the wires fell off. However, I'm quickly learning that most things can be fixed. The wires were more tedious than anything, not difficult, just tedious. The capacitor replacement was very easy and is another case of these old electrolytic capacitors failing due to age.

You can contact me if you are having trouble with your remote. I am not an expert and only do this as a hobby, but I may be able to provide guidance.

|